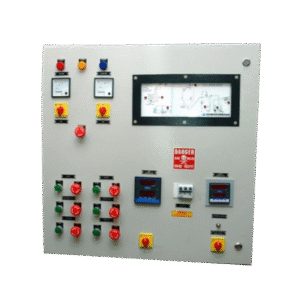

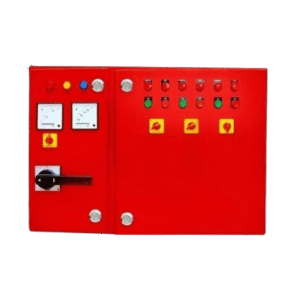

Key Features

Centralized control of all STP equipment: pumps, blowers, mixers, and valves

PLC-based or relay-based control with customizable sequence logic

Real-time monitoring of motor status, faults, and process timing

Auto/Manual operation modes with selector switches for individual equipment

Integration with level sensors, float switches, DO (Dissolved Oxygen) sensors, and timers

Built-in protections: overload, short circuit, phase failure, dry run

Visual and audible alarms for abnormal conditions (motor fault, high/low level, blower trip)

Indications: Power ON, Equipment Run, Fault, High/Low Tank Level

Optional SCADA or BMS interface via Modbus/Ethernet

Expansion-friendly design to accommodate future upgrades or plant expansion

Technical Specifications

| Parameter | Details |

|---|---|

| Brand | Power Pro |

| Phase | Three-Phase |

| Operating Voltage | 380 – 440V AC |

| Frequency Range | 50/60 Hz |

| Pump Types Supported | Centrifugal, submersible (typical) |

| Hp Range | 0.5 HP to 5 HP |

| Panel Material | CRCA sheet , Powder coated. |

| Feedback Device | Pressure sensor or flow sensor |

| Cooling Method | Forced cooling (for >15 HP) |

| Control System | Pressure switch-based or sensor-based (VFD) |

Applications

- Commercial, industrial, and residential sewage treatment applications

- Compact and large-capacity STP plants

- Continuous or batch-type sewage treatment systems

- Ensures automated operation, water quality compliance, and minimal operator intervention