Key Features

Centralized control for entire WTP process, including UF module integration

PLC-based automation with precise process sequencing and interlocks

Multi-stage equipment control: raw water pumps, dosing pumps, UF skid, backwash pumps, and air blowers

Auto/Manual operation modes for each stage

Real-time monitoring of flow, pressure, and tank levels

Automated backwash and forward flush cycle for UF membranes

Sensor interface: turbidity, pressure differential (ΔP), conductivity, level switches

HMI or touch panel for intuitive control and data visualization (optional)

Safety interlocks and alarms for pump dry run, membrane high pressure, low level, motor trip

Communication-ready: MODBUS, Ethernet, for SCADA integration

Alarm history and event log (in HMI/PLC version)

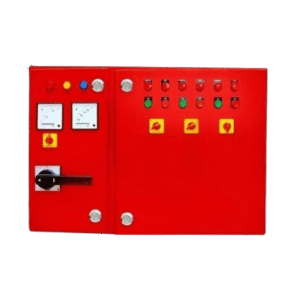

Technical Specifications

| Parameter | Details |

|---|---|

| Brand | Power Pro |

| Phase | Three-Phase |

| Operating Voltage | 380 – 440V AC |

| Frequency Range | 50/60 Hz |

| Pump Types Supported | Centrifugal, submersible (typical) |

| Hp Range | 0.5 HP to 5 HP |

| Panel Material | CRCA sheet , Powder coated. |

| Feedback Device | Pressure sensor or flow sensor |

| Cooling Method | Forced cooling (for >15 HP) |

| Control System | Level switches, DP switches, conductivity probes, pressure transmitters |

Applications

- Industrial and commercial wastewater recycling

- Complex treatment systems requiring high-purity effluent

- Zero Liquid Discharge (ZLD) applications

- Hotels, hospitals, food & beverage, and chemical industries with reuse standards

- Efficient, automatic operation with low manpower requirements